MEP Studio is the new and exclusive visualization software for in-depth exploration of bike pedalling. It seamlessly works with MEP PRO crank arms, onto which various sensors are installed, and provides you scientific data to support your bikefitting analysis. Test your bike setup hypothesis and determine the best one by carefully observing how each leg behaves on the pedals.

Download the slides about the latest version 2018.2 [PDF]

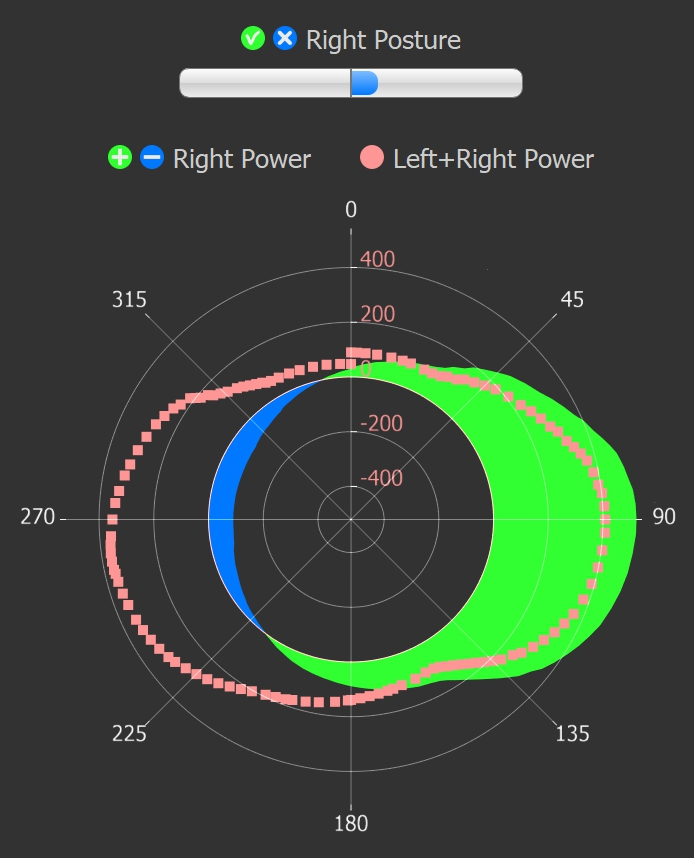

The MEP PRO system measures how much each leg pushes on its pedal and the position of the pushing force over the pedal, highlighting the posture. By comparing this position against the position of the cleat, it is possible to determine foot pronation and supination issues. The technology for this measure is patented and provided to you exclusively by MEP PRO.

MEP Studio has plots specifically designed to represent legs behaviours along the whole stroke in intuitive way. You can thus evaluate even local trends of the pedalling power, distinguishing between positive and negative power (i.e. push/pull phenomena); at the same time, you can compare adding the contribute of the other leg.

MEP PRO integrates a rotation sensor which is perfectly aligned to the axis of the spindle to grant maximum precision. MEP Studio then detects angles at which the pushing phase begins, ends, and reaches its peak.

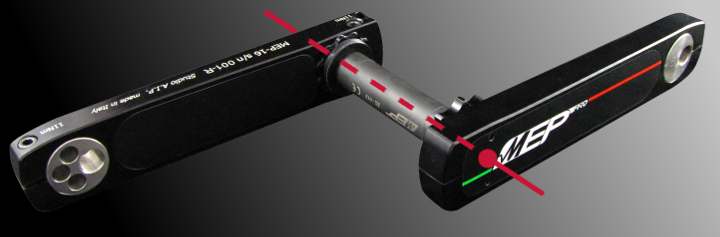

Each MEP PRO crank arm independently scans the pedalling. At the same time, both crank arms are interconnected by wire though the spindle. This way, true data is measured for each leg, while synchronization is granted by construction. You can handle and compare left and right data at any point throughout the rotation, up to 200 times per second.

Set proper pedal length of MEP PRO crank arms by rotating the length adjuster. Play with 7 different lengths ranging between 165 mm and 180 mm without replacing any component. All you need is to loosen a screw, rotate the adjuster, and tighten back the screw.

After years of in‐depth research and experimentation, Studio AIP engineers and technicians present MEP PRO crank arms. The system is specifically designed through computations and simulations to perform accurate, repeatable, and reliable measures. The whole project was then intensively tested on several Test Benches tailored to check precision and reliability over time.

In the production line, each MEP PRO crank arm is calibrated with a strict protocol to check that each parameter is corretly measured. Further checks are performed upon custumer's request, to test power, posture, and rotation measures.